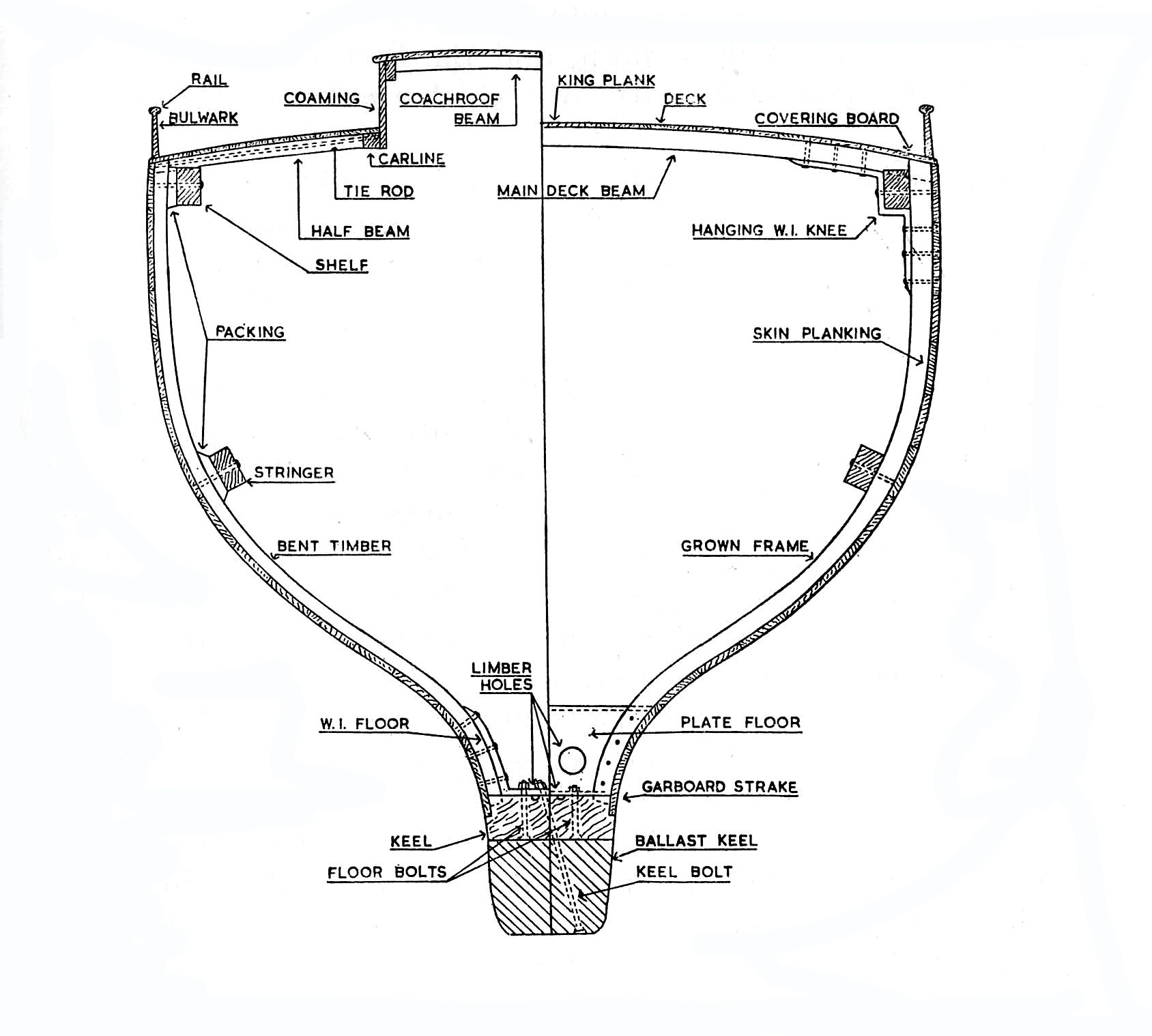

A few of the names that describe the parts of a wooden boat, here in cross section. Note the timber is of less thickness than a frame – boats might have timbers between frames – but each side of the vessel would be symmetrical. The diagram also shows a plate floor and a bracket floor made of wrought iron. In a wooden boat the floor is more likely to be a substantial timber that runs transversely across the top of the hog (the internal part of the wooden keel) and joins both port and starboard frame bilge futtocks (ends) at the centreline.

Wooden boatbuilding usually begins with the keel (being laid) and then the rib-cage of frames are erected from it, along with some of the deck structure. After that planking takes place with planks being steamed first to make them soft enough to bend to the shape of the frames. These are most usually clenched in place with copper or bronze (if there is enough money) nails and roves in a process known as fastening.

The lowest plank, next to the keel is known as the garboard or garboard strake while the top plank is known as the sheer strake.

The longitudinal strength of a wooden boat comes from the keel, the stringers, which run from stern to stem, and the beam shelf which also supports the deck beams.