A new sailing cargo ship is being built in Costa Rica

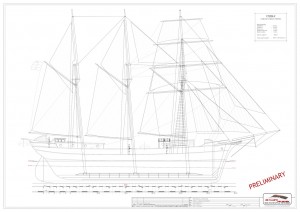

This is an exciting project! Designed to deliver carbon negative marine freight the 155ft (47m) three master is at the lofting stage with massive baulks of timber arriving to the site in the jungle where the team has assembled to build the vessel, which will be named Ceiba. Appropriately they have called themselves Sailcargo. This is an interview with the team with photos reproduced with kind permission of Sailcargo (click on images to expand). CS questions are in bold.

aKJFkXqrLb8

CS: How did CEIBA come about?

Sailcargo: Several friends who met onboard the Tres Hombres were inspired to begin a larger, financially sustainable sailing cargo ship.

Lynx Guimond Co Founder & Technical Lead World class woodworker Lynx Guimond lives in Costa Rica; he has crafted figureheads and carvings on Sørlandet, Europa, Morgenster, and many more. His pieces – such as the windlass on Tres Hombres – are unparalleled. Originally from rural Québec, Lynx’s work style resonates with those who have the pleasure of working with him. Over the past six years, Lynx has been designing and building treehouses in the Costa Rican jungle and aiding in the treetop traverses designated for biology research. To see more of his visionary work, check out his website.

Danielle Doggett Co-Founder & Director Sailcargo Inc. Managing Director Danielle Doggett has 14 years experience on traditional ships & specific project management skills for sail-cargo initiatives. Growing up just north of Kingston, Ontario, she began her sailing career with the St. Lawrence II, moving onto larger ships at age 16: Swan fan Makkum. Founder of Topsail Rigging Ltd., she has focused her attention in recent years to gaining knowledge of the build stage of large scale projects, including working alongside Sailmaster B.V. in the Netherlands. She is an adviser to the Caribbean Sail Training Association, and was Captain of the flagship of Barbados, sailing cargo schooner Ruth for the rigging, launch & sea trials.

Danielle Doggett Co-Founder & Director Sailcargo Inc. Managing Director Danielle Doggett has 14 years experience on traditional ships & specific project management skills for sail-cargo initiatives. Growing up just north of Kingston, Ontario, she began her sailing career with the St. Lawrence II, moving onto larger ships at age 16: Swan fan Makkum. Founder of Topsail Rigging Ltd., she has focused her attention in recent years to gaining knowledge of the build stage of large scale projects, including working alongside Sailmaster B.V. in the Netherlands. She is an adviser to the Caribbean Sail Training Association, and was Captain of the flagship of Barbados, sailing cargo schooner Ruth for the rigging, launch & sea trials.

Where are you based and why?

We are based on the Pacific Coast of Costa Rica, on the Gulf of Nicoya. This location was strategically chosen in that the build of Ceiba ties in perfectly with Costa Rica’s goal of becoming the first carbon-neutral country by the year 2021. It is also because of the country’s friendly business environment and its geographic location situated ideally between North and South America with access to both the Pacific Ocean and Caribbean Sea.

How did you choose this type of ship? (Is there a connection to Tres Hombres here?)

It’s funny – while there is no specific tie to Tres Hombres, the two vessels have to thank the same architect (Pepijn van Shaik of DVS Marine Design) for the technical drawings – so perhaps there are more subtleties in common that we can be aware of!

The design and performance will be important so can you say more about the development of the topsail schooner?

The development of the square topsail schooner that we see here today has a long history that draws upon many influences. Ceiba’s design stems from a design of the early 1900s: the Ingrid of the Finnish Aland Islands, where the famous fleet of Gustav Erikson called home. The topsail schooner is ideal for coastal trading, where versatility was of the utmost importance. When sailing around island and diverse coastlines the winds change rapidly, so a manoeuvrable vessel is key. Whether two or three-masted, square topsail schooners have always been prized for offering a satisfactory performance on all points of sail, while requiring relatively few crew.

For instance: a vessel may need to sail upwind through a maze of islands, for which a schooner rig allows excellent tacking ability. When the time comes to drop or raise anchor, the square sail provides power and control for box-hauling or setting the hook.

How many ships like this are trading now?

Five vessels are actively trading and several smaller craft are as well:

1. Tres Hombres (operated by Fairtransport);

2. Nordlys a ketch (operated by Fairtransport)

3. Grayhound (Logistics provided by TOWT Trans Oceanic Wind Transport);

4. Ruth (Flagship of Barbados);

5. Avontuur (operated by Timbercoast)

How will you carry cargo? What types of cargo will you have?

Cargo will be carried in the cargo hold below deck. There will be a capacity of 250 tonnes (350+ cubic metres) with more available on deck if necessary. Currently we already have secured letters of intent from prospective clients who would like to ship their coffee and cacao beans with us under sail. There are opportunities for many other ethical products to be shipped with us, some of which may include vanilla, cotton, salmon, turmeric and macadamia nuts – all sustainably sourced and fair; cargo inline with the values of SAILCARGO INC. We are also open to other types of cargo as long as they match with our company’s mission to ship sustainable products emission-free.

Will you be able to sail all year round?

Yes, being cautious to avoid hurricane-sensitive zones during hurricane season.

Is there a market for your kind of products – to be specifically shipped under sail?

Absolutely! Our market is quickly emerging. Thanks to the work of countless people around the world over the decades, the general public now has an understanding of the environmentally devastating effects of the status-quo shipping industry – and they want to see a change. Goods that can boast zero carbon footprint stand a head above the rest, and retailers know this. Take coffee being enjoyed in the UK right now. Even if the coffee beans are organic, fair-trade and use biodegradable packaging, every single cup has been brought into the country using a combustion engine… that is, unless it was sailed there. Coffee lovers in Vancouver and Seattle know this and are eager to support clean cargo initiatives by voting with their purchases.

Can you insure products, or their time of arrival? Is that important?

CEIBA will have a comprehensive insurance policy – in addition to this we encourage clients to consider purchasing their own insurance additionally. As an international service provider, arriving into ports on time is critical to our value proposition: it is a key deliverable to our clients, and our best way to develop lasting relationships with them. To ensure our arrival times we have calculated our voyage times using conservative estimates. By choosing a conservative average speed we incorporate flexibility into our scheduling: it is likely that Ceiba will arrive into ports ahead of schedule, allowing for additional unloading and maintenance time. Another way we will be able to ensure arrival times is our electric engine, which will be responsible for propulsion when the winds are unsuitable. Due diligence and a commitment to building in redundancies is our strongest asset in guaranteeing a dependable service.

I think it is important to note, however, that external factors will always effect our ships and all ships on the water. Time and time again people ask us if we will be able to guarantee times, often inferring or insinuating that the modern shipping fleet operates without delays. Large container ships can often be held up in ports for upwards of two weeks – waiting on port delays, lineups for container cranes, to bunker fuel or for other factors. While Ceiba will have unique factors of her own to consider, many of these causes of delays will simply not apply: our vessel is can contract standard dockside cranes, but also remains a self-sufficient ship capable of loading and discharging cargo with her own booms and electric winches: Ceiba will never have to wait in line for cranes, to use port tugs or to bunker fuel.

How many crew will there be?

Twelve permanent crew and up to twelve additional guest crew.

Will you train them? If so what kind of certification will be offered?

We will train our ”green hands” to grow from deckhands to officers using proven, respected methods. Co-founder Danielle began her career sailing onboard the brigantine St. Lawrence II out of Kingston, Ontario: this ship is the longest running youth sail training vessel in the world. With roots with this organization and many other sail training vessels, Danielle moved on to write a sail training procedure for schooner Ruth, flagship of Barbados, earning her a position as Adviser to the Caribbean Sail Training Association.

While it is likely that an in-house certification will be awarded, it is really the sea time that is important for those sailing onboard. When sea time is officially logged on a vessel of certain tonnage, the crew member may then take that certified time to accredited educational academies or to their own government to write exams and obtain licenses. Regulation stipulates that seafaring courses are internationally regulated and accepted, such as STWCs Basic Safety and higher – and our sea time will fit into this model.

How many crew will be paid?

On average we estimate that eight of the twelve permanent crew will be paid, with four apprentices.

Is this a career for someone who wants a life at sea?

Yes! Not only is this a wonderful way to learn and improve traditional skills, but Ceiba will offer a working environment based on sailing with a true purpose. When it comes down to it, I get tired of endless day sails, serving guests and explaining once again how to properly haul on a halliard… when you’re sailing deep sea cargo voyages, you get to work with people for a long time; you get to hone your skills and drive the ship as hard as she can to make the next port of call. It isn’t competitive pressure to win a race, it’s personal determination to do the best you can – for the ship and for the cargo.

Where will you be sailing? (Just in the Pacific?)

That is the plan, yes. Ceiba will be sailing The Pacific Exchange (PAX) Line, which is the first shipping route developed by SAILCARGO INC. Voyages on this line will ship cargo as far west as Hawaii, south to Peru, northbound to Canada, down past California and home again to Costa Rica. Once the ship is complete, she will complete this route twice annually. Part of the reason behind choosing the Pacific is because currently there is no option for shipping under sail with a carbon-neutral footprint on this side of the world – Ceiba fills that void for her customers.

Why build her in wood? (Isn’t it cheaper in steel?)

When asking if it is ”cheaper” to build in steel, we calculate the cost to the environment – so no, it is not cheaper to build in steel. We are also able to have access to and source almost all of our wood sustainably and locally from Costa Rica. For example, we have sourced much of our huge hardwoods (Tamarindo del Monte) from Upala, a region only a few hours north of us close to the border with Nicaragua. These massive trees are also all storm-fallen; they came down in the hurricane in 2017, which means that by buying and using this wood, we are ‘up-cycling’ it in a sense by keeping the carbon locked in and stopping it from being released into the atmosphere through biodegradation and instead giving it a new life and purpose in reducing emissions even further once shipping cargo under sail.

How important is carbon neutrality to the project?

Paramount. It forms one of the three main pillars of the project and is one of our most important considerations when taking any new step toward the build of Ceiba. Throughout the project, we want the overall output to be neutral or even better, carbon-negative and regenerative. One step we have been taking since the inception of the company, is planting thousands of new trees to continuously offset any emissions that are being created throughout. The minimum will be to just offset, however, in reality we want to give back in way which not only sustains the environment we co-exist with, but to “improve” on the current situation by planting more than we have taken – to sustain and then regenerate will be our way of giving back.

The reason this is so important: shipping is carrying 90% of the world’s cargo, the environment, at a bare minimum, is not even being healthily sustained, and the industry at large is responsible for numerous ongoing and negative environmental damages. Therefore, as consumers, producers and shipbuilders, we have the responsibility to make the changes needed, on all levels, to efficiently, ethically and truly sustainably improve the industry to allow it to continue to thrive for many years to come, and not to just exist at the expense of the natural environment.

Can you explain to a layman what carbon neutrality means?

In the case of building and employing Ceiba and the running of the company, it means any negative output created at the detriment of the environment is equally offset by the active positive input of carbon-reducing measures put in place, such as the planting of trees or using only the power of the wind or the 100% electric engine whilst running the ship. In short, the ship or the company, during all stages, does not emit more than what is given back – the effect on the environment is neutral.

How far into the build process are you?

After years of development our technical drawings and design are complete; we have 25% of the lumber now milled up to dimension here at our shipyard. A significant amount of our framing stock, deck-beams and centreline elements (such as the keel and deadwood) are drying, waiting to be used. Over the next months we will simultaneously continue to mill more lumber, move onto lofting and lay the keel of Ceiba.

Who is building the ship?

Our team is comprised of both national and international persons. We aim to maintain an overall average of 50% Costa Ricans. We also have a combination of volunteer and paid crew; a significant amount of labour has been volunteer to this point, accounting for nearly all of the shipyard infrastructure. In the coming months we aim to bring on people with specific shipbuilding skills from around the world to begin constructing Ceiba.

How much will she cost and… How are you funded?

This is really one of the most interesting and unique aspects of our project: as we are for-profit, people may purchase stock in the registered company, thereby becoming owners of the ship, Ceiba. Our fellow investors are not only directly supporting our progress, but also look forward to receiving healthy dividends annually for the entire working lifespan of the ship – which could be 100 years. By the end of our build we estimate that approximately 75% of our team will be shareholders of Ceiba. We are entirely funded through people buying stock, so maintaining strong personal relationships with every single shareholder is something we focus on. The estimated cost of Ceiba is $3.6million US.

So, how can people get involved?

There are three main ways people can get involved.

- Invest in shares in the company! Check out our extensive Business Plan to find out more or contact Danielle at info@sailcargo.org.

- Join the team! Volunteer your skills here at the shipyard in beautiful Costa Rica.

- Ship your products with us! Want to close the loop in your already sustainable product line? Contact us to find out more.

- *Bonus* – Share, Share, Share! Find us on social media, share the project and tell all your friends and family about us to help us spread this important message, so that together, we can #seashippingchange.

See more: www.sailcargo.org Tel: (+506) 8625 0909

Youtube: SAILCARGO INC. Watch Our Official Intro Video!

Carbon Negative Marine Freight – C O S T A R I C A

CS thanks Shani Meintjes for helping organise this interview