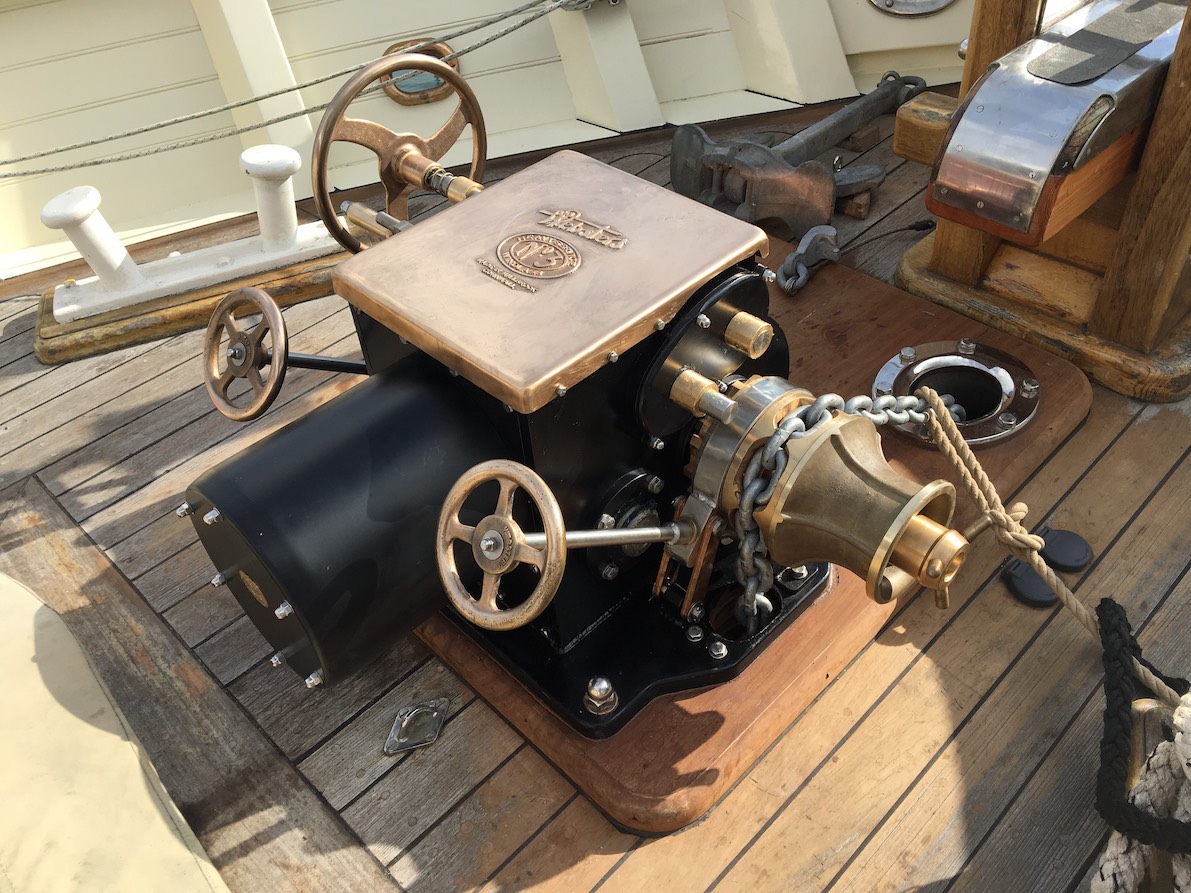

David Webster was asked by Stirling & Son to make a powered version of his Webster’s No.2 model windlass, for a vessel they were working on at the slip in Plymouth. “I wanted to be confident that the windlass would offer a viable manual option, as opposed to the inadequate manual back up on many other powered windlasses. Given her new 150Kg anchor and 120m of 16mm chain, it would need to be a powerful piece of machinery,” he tells CS.

But with the Webster’s No.3 windlass having been in design for some time, and given the need to incorporate additional gears, a second gearbox and electric motor, he took the decision to use the No. 3 model platform, as a larger and more powerful machine, for this project.

The windlass has a single gypsy, but David also wanted it to be possible to deploy a second, relatively heavy anchor on rope, from the port side warping drum. For this reason he installed a strong brake, of the same specification at both sides of the windlass.

The Webster’s No.3 model windlass has been developed for expedition vessels, large yachts and small ships, and is currently the largest standard windlass in the range.

David is currently working on the windlass for Luke Powell’s new project the Pellew Falmouth pilot cutter.

Deep Blue Engineering Ltd